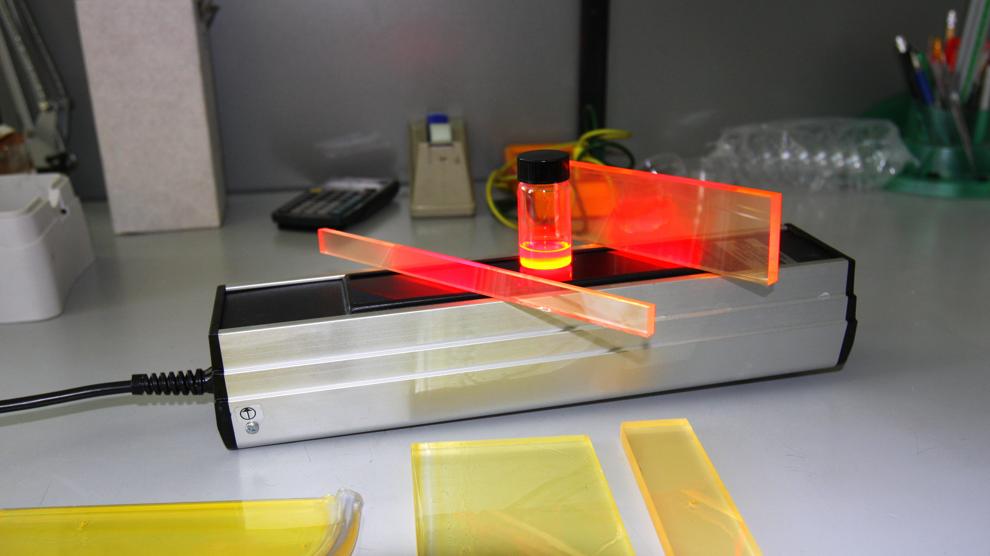

The first industrial plant for the production of CIS nano particlesis already in the start-up phase in Rovereto. Recall that the latter are the key players for the conversion of sunlight into infrared radiation within Glass to Power’s photovoltaic double-glazing unit.

The design of the plant took place in several stages through careful and in-depth analysis of the chemical and thermodynamic kinetics of the synthesis protocol developed by Glass to Power within the Milano-Bicocca laboratories. This protocol, initially created on a small production scale from half a gram to synthesis, has seen a progressive adjustment and optimization at first by the Bicocca and then the Rovereto laboratories.

The latter, through an increase in the laboratory scale equal to 4 grams per synthesis, have made it possible to highlight the critical aspects linked to the industrial perspective, providing preliminary indications of a structural, energetic and economic nature necessary to outline an adequate, efficient and easy industrial process. For the conception of the entire production apparatus it was obviously essential to go through the design of an “intermediate pilot” plant from which it was possible to extrapolate those very important project data fundamental to the calculation of the reactor (the heart of the process) and of all auxiliary and control equipment complementary to it.

Thus, the necessary bases have been created to address the analysis of risk factors related to industrial safety as well as the conduct of reactions on a larger scale where those thermodynamic and kinetic “parasitic” phenomena inevitably take over. The latter, if not adequately addressed at the preliminary design level, inevitably lead to distorting or polluting the final identity of the nano particle with drastic consequences in terms of the overall efficiency of the double glazing.

Industrial risks and parasitic phenomena have therefore traced the design path of a plant of considerable size able to guarantee safety at high temperatures for long periods of time, as required by the protocol, and the precision of conducting certain reaction steps that lead to a specificity in the final identity of the nano particle.

The current industrial plant will be able to safely produce 250 grams of nano particles per day, therefore equivalent to 1 kg per week. This last quantity will allow the achievement of a first production step of double glazing equal to about 130 square meters per week. It should be emphasized that the design exercise of this new plant will be essential to undertake the design of the future2-3 kg plant with a daily synthesis (and therefore 10 times larger than the current one) to make up for a production of photovoltaic panels greater than 300 sqm/day.

It is of great importance to add that in the design of the current plant particular attention was paid to its management versatility, which is essential to ensure the possibility of hosting synthesis protocols of different nano particles in a fairly easy way.